The Silhouette Curio 2: The Newest, Bestest Home Cutter for Scale Modelers

When Silhouette announced their newest series of home cutters, including the Portrait 4 and Cameo 5, what really jumped out at us was the redesigned Curio 2.

(Please note: Hawaiian Air Depot provides links as an Amazon Associate. We shop around for the best products at the best prices so your Hawaiian Air Depot designs are easy, fun, and economical to use. If you want what you see, please navigate through the link for purchase. We’ll earn a small commission when you do, and hey, if Amazon pays for all of this then we can quit our day jobs to make more, better designs while keeping our prices low.

If not, support your local hobby shops and art supply stores!

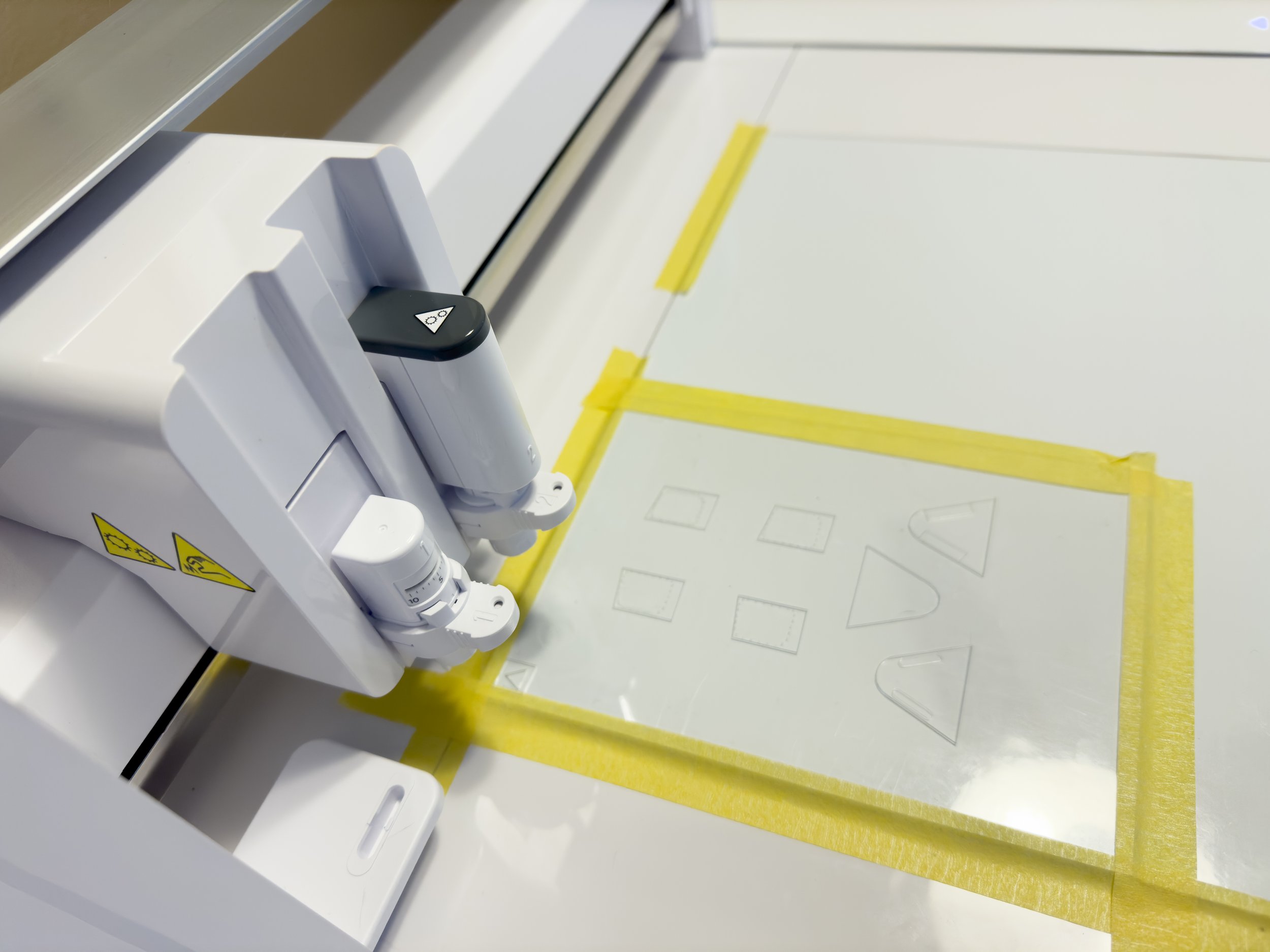

Unlike any other home machine on the market, the Curio 2 is now a flatbed cutter. A mat no longer rolls around under a traversing blade. The cutting surface remains stationary while an overhead rig moves the blade around.

Here we are putting our new Curio 2 through its paces by cutting the clear styrene for our McCampbell’s Minsi design for the 1/24 Airfix F6F-5. Note the moving cutting head above the styrene. Pictured are the rear window and headrest options for depicting the clear windows.

Let’s get the bad news out of the way first: The Curio 2 is BIG. Heavy too. It takes up a 20 x 24-inch space on the workbench. And it won’t easily store away and pull out for use like the Portrait. It’s rather tall as well, with the top of the blade housing sitting just shy of 10 inches over the table top.

And retailing at $430— same as the Cricut Maker 3.— it’s also one of the most expensive home cutters on the market.

So upgrading to the Curio 2 is a big investment. But if you— like us— see producing your own parts and masks as a growing aspect of your scale modeling, you should seriously consider this thing.

We’ve had the Curio 2 running for about a month now and we still haven’t put it through all of its paces, but the early results are justifying our initial excitement. Let’s begin with a list of the main differences between the Curio 2 and other cutters:

That moving cutting arm: This is a commercial machine feature that Silhouette brings to the home market. They claim it should result in more precise and delicate cuts. More precision and finer detail? Yes please.

The Electrostatic Bed: Rather than a sticky cutting mat, The Curio 2 develops a charge of static electricity that holds smooth materials in place. This promises two advantages for scale modelers: superior immobilization resulting in more accurate cuts, and when complete the materials need not be peeled from the adhesive, meaning no more tearing, curling, or residue on your finished product.

Smart Detection: The second carriage on the Curio 2 is now charged for power tools like an engraving tip. While we haven’t yet discovered a use for the available power tools (still looking), the charged carriage also houses a depth sensor which adjusts the cutting head by measuring the material on the bed. Smart Detection promises less material wasted on practice cuts.

Intelligent Path Technology. IPT is a new feature of the software interface that manages the cuts. What it does is reorganize cuts into similar blade angles, rather than just following the lines of the pattern. Grouping the cuts this way reduces the instances where the blade pivots on a curved line. Silhouette says it’s a big part of what improves the quality of delicate and complicated cuts.

Also improved are the cutting force, speed, and noise of the machine. They now rival the Cricut Maker 3. The quality of construction eclipses the last generation of Silhouette machines as well. Seems like they recognized what Cricut is doing better and managed to close the gap.

So how did they do? We’ve got enough work under our belts to offer some initial observations.

Generally, the cuts seem more precise than the Cameo and the Portrait. Basic cuts look great on all 3, but the really fine stuff is coming out a little crisper and with less errors on our Curio 2. The combination of the new features appears to deliver what Silhouette promises.

The Electrostatic Bed is the feature we were most excited about. We imagined materials stuck like a sword in stone, then magically released without tearing and curling up. Cause science.

Nothing is ever as good as you dream it will be. We can’t get our Electrostatic Bed to immobilize materials well enough to just hit the button and let ‘er rip. After a few tests, we found we still need to tape stuff down. Here, the anticipated benefits didn’t quite meet our expectations. Insanely high expectations.

It’s still performs better than adhesive mats, though. Especially when cuts are completed; removing cut material is indeed easier and damage free. For that reason alone, we’re fans of the new design, though we hope the quality of the electrostatic bond can be improved over time.

While our greatest expectations wasn’t quite realized, we didn’t appreciate what a benefit Smart Detection and Intelligent Path Technology would be. We like surprises!

For scale modelers using earlier machines, cutting sheet styrene is the biggest challenge, with a steeper learning curve and higher failure rate than masking materials. Getting a cut at the perfect depth—where parts were easily removed but the blade doesn’t carve up the mat underneath— is a bit inconsistent and unreliable. On the Portrait, Cameo, and Cricut the Maker we would typically cut a design 2 or three times to get enough well-cut parts for a complete set. Even then, parts would often need to be persuaded with a scalpel blade to break free the sheet

The first two .010 styrene cuts we tried on the Curio 2 were brilliant. When complete, we removed the styrene from the electrostatic bed and a few perfectly cut parts just fell right out. The rest were barely attached, popping free with a gentle push. The bed protector didn’t have a scratch on it. We were assembling our new parts after a few minutes of fine cleanup, rather than a half-hour of careful nudging, prodding, and prep.

The parts just popped out of those beautiful, elegant, spaces. We just cried. Normally, when we cry while building a model, it is for a totally different reason.

This alone offers the potential for more elaborate and efficient part-making than any of the earlier Silhouette and Cricut machines. If it continues to cut thin styrene this well and lives up to the hype of cutting thicker materials, the Curio 2 will be an essential tool for the modern scale modeler and scratch builder.

We used our new Miniart P-47D-25 Styrene Sheet Metal Design to test the Curio 2 styrene cutting abilities. It went really well.

There’s one last potential downside to note: though for us it isn’t a dealbreaker. The Curio 2 takes forever to cut a typical Hawaiian Air Depot product file. Now, most of our product files contain scores of elaborate and delicate shapes, and our Styrene Sheet Metal line typically requires two separate cuts: one for scribing/riveting, and another to cut the parts free. So none cut in the few minutes of a simple design, but the Curio 2 takes closer to an hour than the same design cut in 20 minutes on the Cricut Maker.

The culprit seems to be Intelligent Path Technology. It’s a paradox: the cutting head indeed moves faster but it is traveling around far more during each cut. The approach enables it to pull off more delicate cuts, but the trade-off is time.

So our first tests unexpectedly kept us up past our bedtime. Hating that. But after a good night’s sleep we’ve concluded we are happy to let the machine take as long as it likes to give us the results it did. Plan an early start.

The Curio 2 isn’t for everyone, but in our view it is currently the best cutting tool available for the top end of what we do as scale modelers. For folks who want a a good option to cut masks and parts from thin styrene at an affordable price, The Portrait 3 is still our favorite choice, and nowadays great deals can be found since it is being phased out by the Portrait 4. We haven’t tried the Portrait 4 yet, but our research suggests the big difference is it supports Intelligent Path Technology, so it seems a good upgrade if you want to spend a little more.

But if you’re all in, have the money and the space, the Curio 2 is the machine you want.